Reviving Your Ride: The Ultimate Guide to Alloy Wheel Repair Machines

Reviving Your Ride: The Ultimate Guide to Alloy Wheel Repair Machines

Are you tired of the unsightly dings and scratches on your beloved alloy wheels? Look no further! In this ultimate guide, we will dive deep into the world of alloy wheel repair machines, specifically focusing on the revolutionary wheel repair lathe and its vertical counterpart.

Alloy Wheel Repair Machines have become the go-to solution for car enthusiasts and professionals alike, providing a simple yet effective way to bring back the shine and glamour to your wheels. These machines, such as those offered by wheelcncmachine.com, are the result of years of expertise and dedication from Taian Haishu Machinery Co., Ltd. Their official website showcases their prowess as a professional designer, manufacturer, and supplier of CNC wheel machinery.

With the help of these cutting-edge machines, you can bid farewell to those pesky wheel imperfections that have been decreasing the aesthetic appeal of your ride. The wheel repair lathe, for instance, offers precision and accuracy in reshaping damaged wheels, effectively removing any bends or dents. Its vertical counterpart takes it a step further, boasting a space-saving design while still delivering top-notch results.

Stay tuned as we delve deeper into the world of Alloy Wheel Repair Machines, offering you the tips, tricks, and insights you need to make an informed decision. Whether you’re a car enthusiast looking to restore the beauty of your prized possession or a professional aiming to impress your clients, this guide is here to equip you with all the knowledge you need to revive your ride.

1. Types of Alloy Wheel Repair Machines

Alloy wheel repair machines play a crucial role in restoring the appearance and functionality of damaged wheels. They utilize advanced technology to bring back the original form and quality of alloy wheels, eliminating the need for expensive replacements. In this section, we will explore three common types of alloy wheel repair machines.

Wheel Cnc MachinesWheel Repair Lathe:

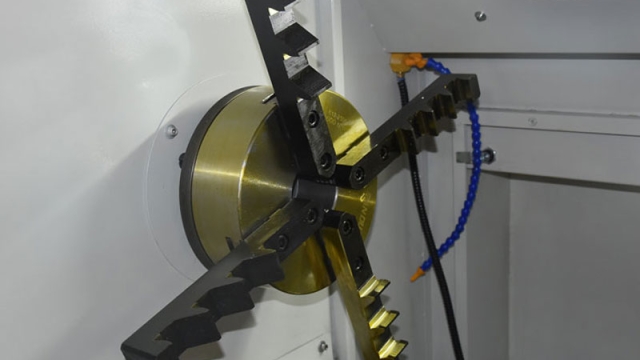

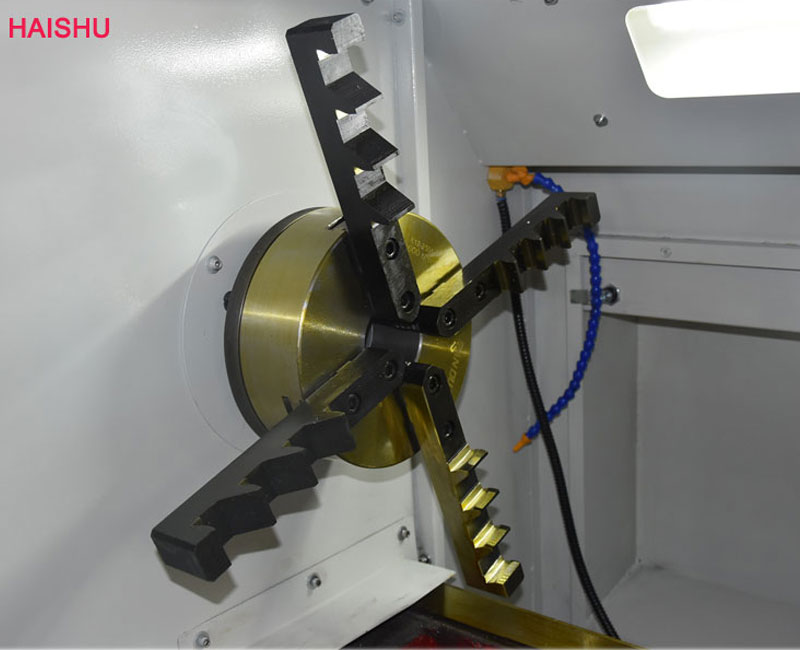

A wheel repair lathe is a versatile machine designed specifically for repairing and refinishing alloy wheels. It employs precision cutting tools to remove damaged areas, such as scratches, dents, and curb rash, and then smoothens the surface for a seamless finish. Wheel repair lathes are ideal for straightening out bends or warps in the wheel rim, ensuring optimal balance and performance. These machines enable technicians to achieve precise results with minimal material loss.Vertical Wheel Repair Lathe:

Similar to a standard wheel repair lathe, a vertical wheel repair lathe offers additional flexibility and convenience with its vertical orientation. This design allows for easy positioning and rotation of the wheel during the repair process. By utilizing a vertical spindle, technicians can access different angles of the wheel with enhanced control. Vertical wheel repair lathes are particularly useful for tackling more complex wheel damages, such as intricate designs or hard-to-reach areas.Alloy Wheel Repair Machine from wheelcncmachine.com:

Wheelcncmachine.com is the official website of Taian Haishu Machinery Co., Ltd., a trusted designer, manufacturer, and supplier of CNC wheel machinery. Their alloy wheel repair machine is a state-of-the-art solution that combines the benefits of precision cutting and automated programming. This advanced machine utilizes computer numerical control (CNC) technology to execute detailed repairs and refinishing tasks with utmost accuracy. With a wide range of customizable features and settings, technicians can reliably restore alloy wheels to their original condition.

In the next section, we will delve into the key features and advantages of alloy wheel repair machines. Stay tuned for valuable insights on how these machines can transform the way you revive your ride.

2. The Benefits of Using a Wheel Repair Lathe

A wheel repair lathe brings forth numerous advantages for those looking to revive their alloy wheels. With precision and efficiency at its core, this state-of-the-art machine ensures your wheels get the repair they need without compromising on quality. Let’s delve into some of the key benefits this innovative tool has to offer.

Enhanced Precision and Restoration

A wheel repair lathe takes wheel refurbishment to a whole new level. It is designed to offer unmatched precision, allowing for precise cuts and repairs to be made on damaged alloy wheels. By removing only the necessary amount of material, the lathe ensures that the wheel retains its original form and maintains structural integrity. This precise restoration helps eliminate any imbalances or vibrations, ensuring a smooth and safe ride.Versatility and Customization

One of the standout features of a wheel repair lathe is its ability to handle a wide range of wheel sizes and designs. Whether you own a small sports car or a larger SUV, this machine can cater to all. Additionally, it allows for customization options, such as creating unique patterns or designs on the wheel surface, providing a personalized touch to your ride. This versatility ensures that your alloy wheels can be restored and customized according to your preferences, adding a touch of style to your vehicle.Time and Cost Efficiency

Gone are the days of costly and time-consuming wheel replacements. With a wheel repair lathe, you can save both time and money. Instead of purchasing new wheels, which can be quite expensive, utilizing a repair lathe allows you to restore your damaged wheels at a fraction of the cost. Additionally, the efficient cutting and repair process of the machine significantly reduces the turnaround time, getting you back on the road in no time.

By utilizing a wheel repair lathe, you can revitalize your alloy wheels, giving your vehicle a fresh and appealing look. The precision, versatility, and cost efficiency that these machines offer make them an essential tool in the world of wheel restoration. To explore advanced wheel repair lathe options, visit wheelcncmachine.com, the official website of Taian Haishu Machinery Co., Ltd., renowned for their expertise in CNC wheel machinery.

3. Choosing the Right Alloy Wheel Repair Machine

When it comes to selecting the ideal Alloy Wheel Repair Machine, there are a few key factors to consider.

- Equipment Capability:

One crucial aspect to evaluate is the equipment’s capability. Look for a wheel repair lathe that offers a comprehensive range of features to meet your specific needs. This may include functions such as precision cutting, polishing, and refinishing. A vertical wheel repair lathe is also worth considering, as it can provide additional convenience and efficiency in your repair tasks.

- Durability and Quality:

The durability and quality of the Alloy Wheel Repair Machine are essential for long-term productivity. Ensure that the machine you choose is made of high-quality materials, built to withstand the demands of regular use. Look for reliable manufacturers or suppliers, such as wheelcncmachine.com, providing robust and dependable machinery.

- User-Friendly Interface:

An intuitive and user-friendly interface can greatly enhance your repair experience. Look for an Alloy Wheel Repair Machine with a simple and easy-to-navigate control system. This will help streamline your operations and reduce the learning curve for operating the machinery.

By considering these factors, you can make an informed decision when selecting an Alloy Wheel Repair Machine that best suits your requirements. Remember, choosing the right machine is crucial for efficient and effective wheel repairs, giving your ride the ultimate restoration it deserves.