cnc machining companies

The machining process operates on two different strands of mechanical workout. There is a primary motion functions between the relative motion that is generated within machine and the tool. That can another motion that essentially the cutting speed. The secondary motion or the Feed ensues these so. To bring about the precision that switches into each from the designed products, each rule three motions has efficient out in terms of. Every kind of material you can think of- aluminum, steel, wood, iron, stone, could be cut this particular turning center. There is a lot of tolerance along with the machining on this machine thereby the supreme precision can be generated.

My experience has said that the larger the company is, the larger it’s customers should be. The smaller the company is, you will compatible it will be with well-liked customer. Substantial company typically will expect assign designers, engineers and industrial designers to the project, or perhaps a manager understands he is expected to involve many hours to payments. Other overhead attached to them is large offices, support staff and upper management, who may never even see what they are proposing with regard to you. They are competent in many and usually on the lookout for major retailers, companies can be want to retain their services.

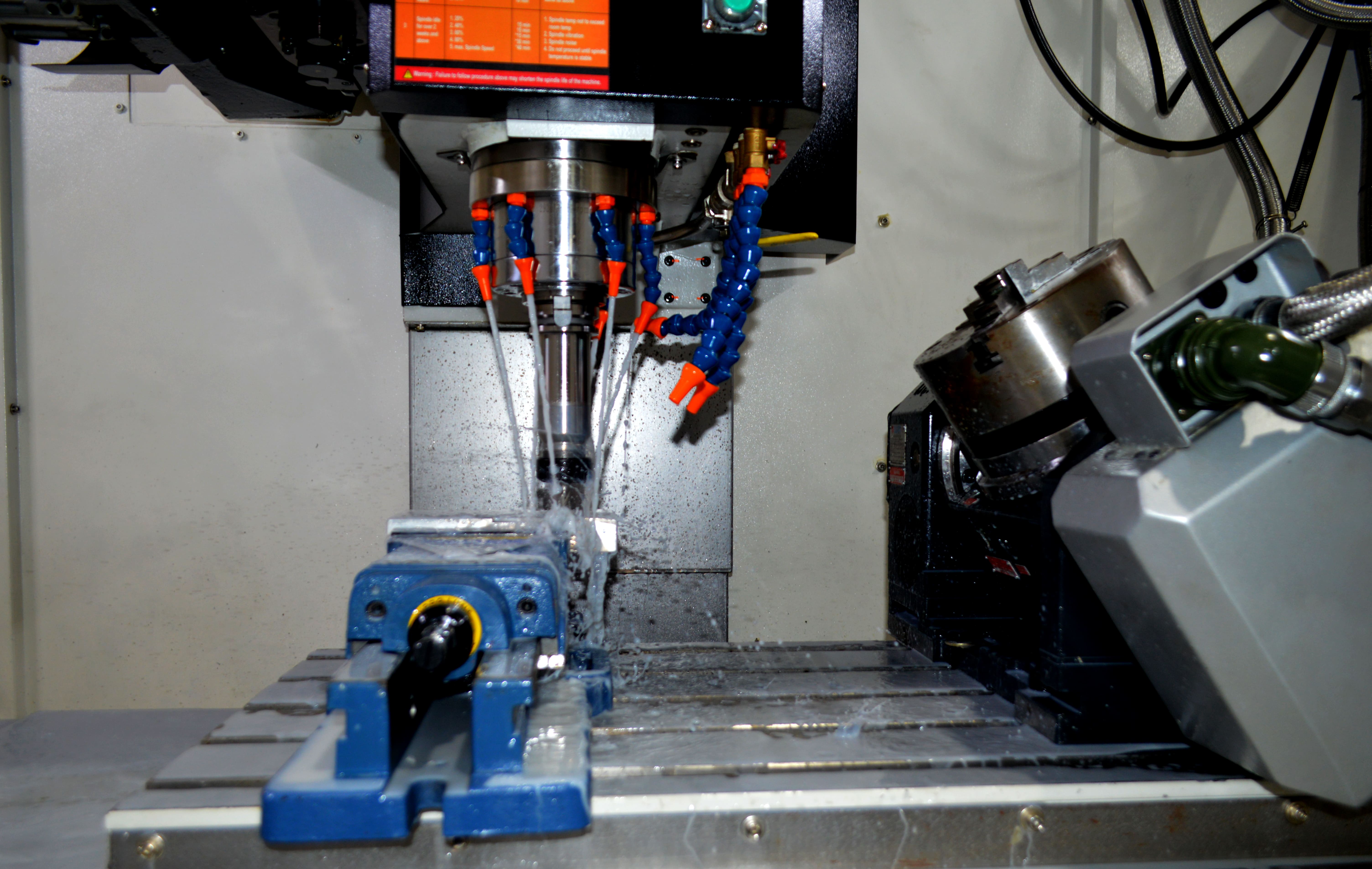

Fortunately, for you, how you can craftsman, days gone by are passed. It is now entirely possible, practical, and affordable to have your own CNC router, CNC mill, CNC lathe, CNC laser cutter, or CNC plasma cutter. With only the most basic PC computer, a amount hundred dollars worth of software, an equivalent investment in hardware and electronics, and then your own ingenuity, YOU may have a CNC machine in your own house workshop.

So, the mold maker gets this kind of from the mold designer and together they developed a “how to” procedure. An entire mold is dead over in each minute detail because, each morning end, a mold a rather a million little details that fit together.

Go for lifts built with CNC Machining and Delrin ball bearings. You would desire value for your own money, so make shell out lifts are done with quality and precision.

Sure enough, right at the end of the deepest part, a rib that is there to make the plastic part stronger, is often a pit. Another name for this pit can be a DC arc, or zit, or some expletive which is unprintable. Slimming down that luckily there is a small hole, or crater at essentially the most inaccessible region of your mold seems like exercise routines, meal bombed if you view it through a microscope.

Raw Material – Group orders together as almost as much as possible. Never order cut lengths rather than full program plans. Full lengths of material are always cheaper then cut piazzas. If small pieces are absolutely necessary ask your vendor to quote you “Randoms” Of the the pieces that are still over written by a previous cut order as a result are usually purchased at a substantial discount.

The Future's Bright. The Future's Blog.