Maximize Your Lift: The Ultimate Guide to Fork Lift Extensions

If you work in a warehouse or industrial setting, you know that maximizing efficiency is key to productivity. One of the often-overlooked tools that can significantly enhance the capabilities of your lift equipment is fork lift extensions. These extensions are designed to increase the reach of your fork lift, allowing you to handle larger loads and improve overall performance.

In this guide, we will explore the benefits of using fork lift extensions, how they work, and the various types available on the market. By understanding how to effectively utilize these attachments, you can elevate your lifting operations and ensure that your team is working smarter, not harder. Whether you are moving oversized pallets or navigating tight spaces, fork lift extensions can be the solution you need to maximize your lift capabilities.

Understanding Fork Lift Extensions

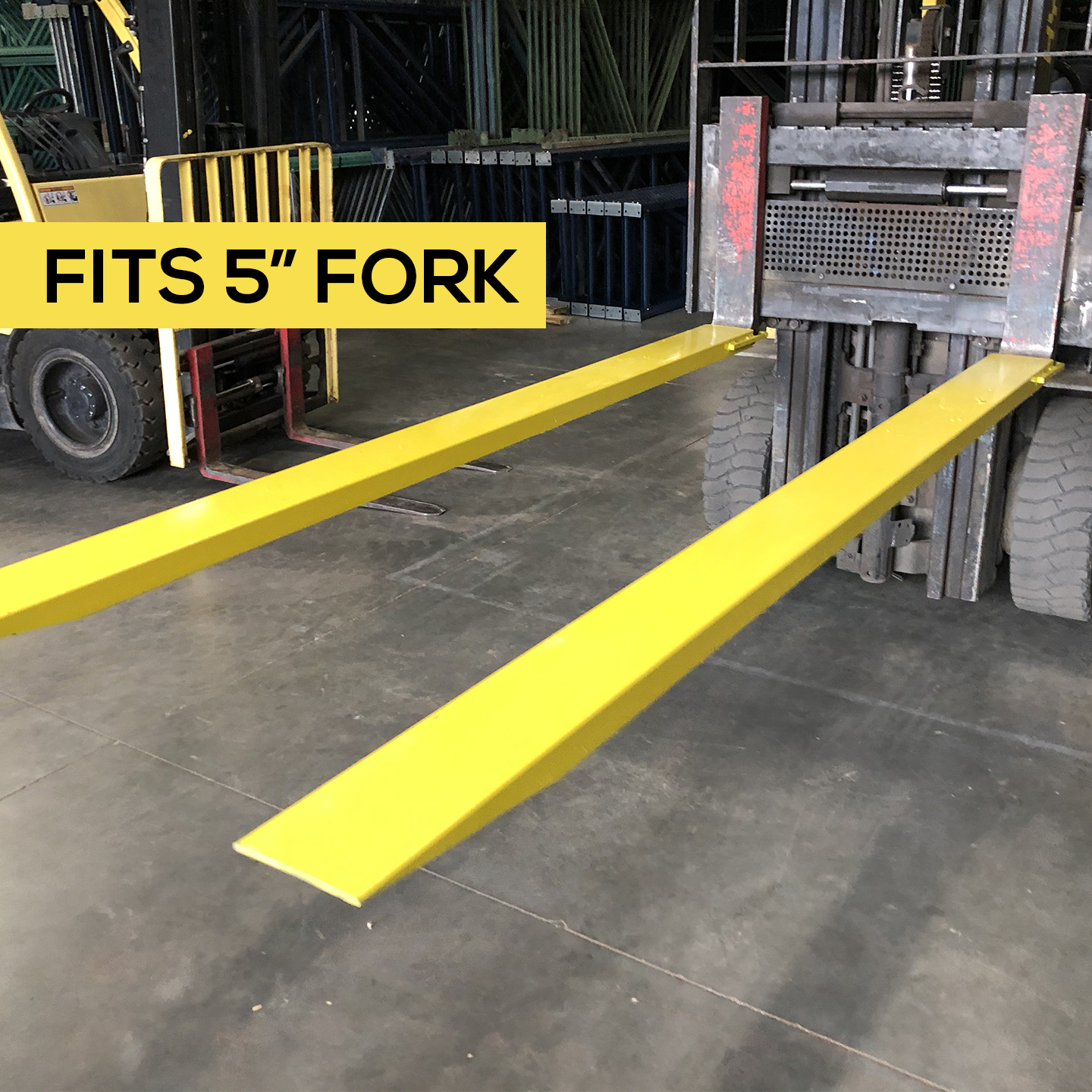

Fork lift extensions are specialized attachments designed to increase the length of the forks on a fork lift. These extensions allow the machinery to handle larger, bulkier loads that standard forks may not be able to manage effectively. They are particularly useful in warehouses and distribution centers where heavy pallets or oversized items need to be moved frequently.

Using fork lift extensions can significantly enhance the versatility and efficiency of a fork lift. By extending the reach of the forks, operators can pick up and transport materials that would otherwise require additional equipment or manual handling. This capability not only speeds up operations but also helps to reduce the risk of potential workplace injuries related to improper lifting techniques.

However, it is essential to understand the proper installation and usage of these extensions to ensure safety and compliance with regulations. Fork lift extensions must be compatible with the specific make and model of the fork lift and should always be used according to the manufacturer’s guidelines. Operators should be trained on how to safely handle loads with extended forks to mitigate risks associated with tipping or overloading the lift.

Benefits of Using Fork Lift Extensions

Using fork lift extensions can significantly enhance the efficiency and versatility of your material handling operations. One of the primary benefits is the ability to lift and handle larger loads that standard forks may not accommodate effectively. This means businesses can transport a wider variety of materials without needing to invest in additional equipment. The extensions allow for better stability and balance when dealing with oversized items, which can lead to improved safety on the worksite.

Another advantage of fork lift extensions is their ability to maximize the reach of your lift truck. This is particularly valuable in warehouses or storage facilities where space is limited and vertical height is crucial. Extensions can help operators reach goods stacked higher than usual without risking damage to the load or the surrounding area. By increasing the effective reach of your fork lift, you can make more efficient use of available vertical space, leading to better organization and increased productivity.

Additionally, investing in fork lift extensions can result in cost savings over time. Instead of acquiring specialized equipment for each type of load or pallet, businesses can utilize extensions to adapt their existing machinery to suit different needs. This flexibility helps in reducing capital expenditure while maintaining operational effectiveness. As a result, companies can streamline their logistics and warehousing processes, ensuring a higher return on investment.

Choosing the Right Fork Lift Extension

When selecting the appropriate fork lift extension, it is essential to consider the specific needs of your operation. The load size and weight play a crucial role in determining the right extension length and capacity. Extensions come in various sizes, typically ranging from 4 to 12 feet, and choosing the right length can significantly enhance stability and safety during lifting. Be sure to assess the maximum load weight your fork lift can handle and find extensions that match or exceed that capacity.

Another important factor is the compatibility of the fork lift extensions with your existing fork lift. Different models and brands may have specific requirements for extensions, including pin size and hook configuration. Verifying that the extensions you choose are designed to fit your fork lift ensures efficient operation and prevents potential safety hazards. Always refer to the manufacturer’s specifications to confirm compatibility before making a purchase.

Lastly, consider the materials and design of the fork lift extensions. High-quality materials such as steel or aluminum can impact both durability and performance. While cost may be a factor, investing in well-built extensions can lead to greater safety and reduced maintenance in the long run. Additionally, look for features like lightweight designs or easy attachment mechanisms that can enhance your overall lifting efficiency.

Installation and Safety Considerations

Check It Out

When installing fork lift extensions, it is crucial to follow the manufacturer’s guidelines meticulously. Begin by inspecting the extensions for any damage or defects before attaching them to the fork lift. Ensure that the extensions are compatible with your specific fork lift model to maintain stability and prevent accidents during operation. Proper installation will not only enhance the lift’s capabilities but also contribute to the overall safety of the work environment.

Once installed, operators should familiarize themselves with the extended lift’s handling characteristics, as the changes in weight distribution and length can affect maneuverability. Conduct a thorough check of the fork lift’s operational limits, taking into account the added capacity that fork lift extensions provide. Always adhere to weight restrictions and consult the vehicle’s specifications to prevent overload situations that could lead to tipping or damage.

Safety gear and practices should always be prioritized when utilizing fork lift extensions. Operators and nearby personnel should wear appropriate protective equipment, such as helmets and high-visibility vests. Additionally, maintain a clear communication system among team members, particularly when operating in crowded or confined spaces. Regular training on the safe use of fork lift extensions is essential to minimize risks and ensure efficient operation.