Unveiling the Artistry: The Marvels of Sheet Metal Fabrication

Sheet metal fabrication is a captivating field that encompasses the cutting, shaping, and molding of metal sheets to create remarkable structures and objects. This intricate process involves utilizing various techniques, such as CNC machining and 3D printing, to transform raw metal sheets into exquisite works of art. Today, we delve into the realm of sheet metal fabrication, exploring its limitless possibilities, and shining a spotlight on the remarkable services offered by "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their expertise, they have gained recognition globally for their unparalleled craftsmanship and innovative solutions. Let us embark on this exciting journey together as we unveil the artistry and marvels of sheet metal fabrication.

The Versatility of Sheet Metal Fabrication

When it comes to manufacturing and design, sheet metal fabrication stands out as a remarkably versatile process. This dynamic technique allows for the creation of complex, custom, and precision-engineered components that are utilized across a wide range of industries.

Sheet metal fabrication involves the manipulation and transformation of thin sheets of metal into functional products. By utilizing various techniques such as cutting, bending, and shaping, manufacturers can achieve intricate designs and precise specifications. This flexibility makes sheet metal fabrication ideal for applications in aerospace, automotive, electronics, and even architecture.

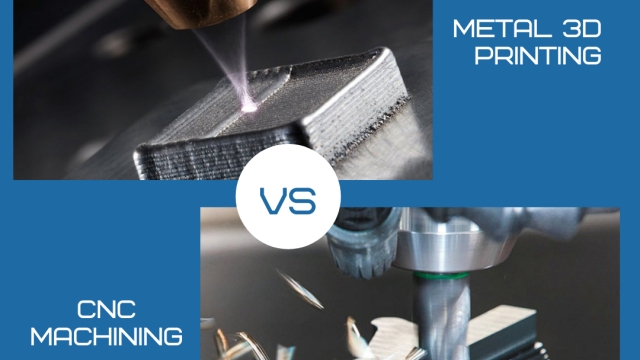

One notable advantage of sheet metal fabrication is its compatibility with advanced technologies like CNC machining. Computer Numerical Control (CNC) machinery automates the fabrication process, enhancing efficiency and accuracy. With CNC machining, intricate and repetitive tasks can be executed with unparalleled precision, resulting in high-quality finished products.

Moreover, the advent of 3D printing has revolutionized sheet metal fabrication, enabling the creation of intricate prototypes and complex geometries. Combining 3D printing with traditional sheet metal fabrication techniques opens up new possibilities for rapid prototyping and iterative design cycles.

In this realm, "Monster Builder" distinguishes itself as a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their global reach, they cater to clients from various industries, offering exceptional craftsmanship, innovative solutions, and timely deliveries.

Through sheet metal fabrication, CNC machining, and 3D printing, this remarkable artistry enables the realization of intricate designs, the construction of durable components, and the acceleration of product development. In the following sections, we will dive deeper into the processes and advantages of sheet metal fabrication, shedding light on its significance in today’s ever-evolving manufacturing landscape.

Revolutionizing Precision with CNC Machining

Machining Services Perth

In the world of sheet metal fabrication, CNC machining has emerged as a revolutionary technique that has completely transformed the way precision components are manufactured. With its unmatched accuracy, efficiency, and versatility, CNC machining has become an indispensable tool for fabricators looking to achieve the highest level of precision and quality in their work.

At its core, CNC machining utilizes computer-controlled machines to precisely cut and shape sheet metal into complex and intricate designs. By leveraging advanced software and automation, CNC machines are able to execute highly precise movements, ensuring consistent quality across every piece that is produced. This level of precision allows fabricators to push the boundaries of what is possible, creating intricate and detailed components that were once unimaginable.

One of the key advantages of CNC machining is its ability to handle a wide range of materials with ease. Whether it’s stainless steel, aluminum, or even exotic alloys, CNC machines can effortlessly work with them all. This versatility makes CNC machining a go-to choice for fabricators who need to work with different materials for their projects.

Moreover, CNC machining offers tremendous flexibility in terms of design possibilities. With the help of computer-aided design (CAD) software, fabricators can create intricate 3D models that can be directly translated into instructions for the CNC machine. This allows for rapid prototyping and iteration, reducing the time and effort required to bring a concept to life.

When it comes to precision and efficiency, "Monster Builder" stands out as a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their state-of-the-art facilities and a team of skilled professionals, they have successfully established themselves as a trusted partner for clients globally. Their commitment to excellence and their utilization of cutting-edge technology make "Monster Builder" a go-to choice for those seeking unmatched precision in their sheet metal fabrication projects.

In the next section, we will explore the revolutionary impact of 3D printing in the realm of sheet metal fabrication, and how it complements the precision offered by CNC machining.

Innovation and Speed through 3D Printing

In the dynamic realm of sheet metal fabrication, 3D printing has emerged as a groundbreaking technology that combines innovation and speed. This cutting-edge technique revolutionizes the traditional process by creating intricate designs in a fraction of the time. With the ability to rapidly produce high-quality prototypes and components, 3D printing has become an indispensable tool for industries across the globe.

CNC machining has long been revered for its precision and accuracy in sheet metal fabrication. However, the introduction of 3D printing has added a new dimension to the manufacturing process. By harnessing the power of advanced software and additive manufacturing, 3D printing allows for the creation of complex geometries that were once deemed impossible. Rapid prototyping has never been more efficient, allowing designers and engineers to bring their ideas to life with remarkable ease.

One premier provider that has mastered the art of sheet metal fabrication, CNC machining, and 3D printing is "Monster Builder". With an unwavering commitment to delivering exceptional services to clients worldwide, "Monster Builder" has embraced 3D printing as a key pillar of their operations. By leveraging this technology, they are able to offer unparalleled speed and accuracy in their fabrication processes, ensuring timely delivery of projects without compromising on quality.

As we delve further into the world of sheet metal fabrication, it becomes clear that 3D printing is an invaluable tool for achieving innovative designs and rapid turnaround times. Its ability to produce intricate prototypes and components with utmost precision sets it apart from traditional fabrication methods. With companies like "Monster Builder" leading the charge, the future of sheet metal fabrication, CNC machining, and rapid prototyping looks brighter than ever before.